A vehicle's suspension and steering components may vary depending on the specific vehicle design and system used. These components work together to allow the driver to control the vehicle safely, maintaining a comfortable and stable ride, even on rough surfaces or in difficult driving conditions.

Each type of suspension and steering has its own advantages and disadvantages, and the choice often depends on the specific needs of the vehicle, the desired performance and the preferences of the car manufacturer.

HERE ARE DIFFERENT TYPES OF SUSPENSION

Independent suspension, dependent suspension, air suspension, hydropneumatic suspension and active suspension.

HERE ARE DIFFERENT TYPES OF STEERING

Rack and pinion steering, recirculating ball steering, hydraulic power steering, electric power steering (EPS), steer-by-wire.

SERVICE TIPS:

Most manufacturers recommend checking the suspension and steering every 12 months or 20 thousand kilometers (12,000 miles).

Air suspension problems are relatively common and can be caused by a variety of factors. EXPRESS AutoCare is equipped to perform a complete system diagnosis, identify the underlying cause of the problem and make the necessary repairs to restore proper operation of the vehicle's air suspension.

We Can Help, Conversion from air suspension to conventional (coil spring) suspension is sometimes considered for several reasons, including reduced maintenance costs, ease of maintenance and increased reliability.

We will first assess whether the conversion is possible and appropriate for your vehicle. Some cars are designed specifically for air suspension and the conversion may be complex or impractical. Converting from air suspension to conventional coil spring suspension has several advantages.

INCREASED RELIABILITY

Coil spring suspension systems are generally simpler and more reliable than air suspension systems, which can be prone to air leaks, air compressor failures and other problems related to their complexity. By converting to a coil spring suspension, you eliminate these potential failure points, which can reduce maintenance costs and improve the long-term reliability of your vehicle.

REDUCED MAINTENANCE COSTS

Coil spring suspension systems are generally less expensive to maintain and repair than air suspension systems. Replacement parts for conventional suspension systems are often less expensive and more readily available, which can help reduce overall maintenance costs and extend the useful life of your vehicle.

EASE TO USE

Coil spring suspension systems are often simpler to operate and maintain than air suspension systems, which can require complex adjustments and adjustments to maintain the desired ride level. With a coil spring suspension, you typically don't need to worry about air pressure, compressors, or air leaks, making daily use of your vehicle simpler and more convenient.

IMPROVE DRIVING PERFORMANCE

For some drivers, coil spring suspension systems provide better ride feel and handling compared to air suspension systems. Coil springs can provide a more direct response to road movements and provide a sportier, more connected driving feel, which can be particularly appreciated by drivers who are passionate about dynamic driving.

Schedule A Quick Appointment (450) 681-1414

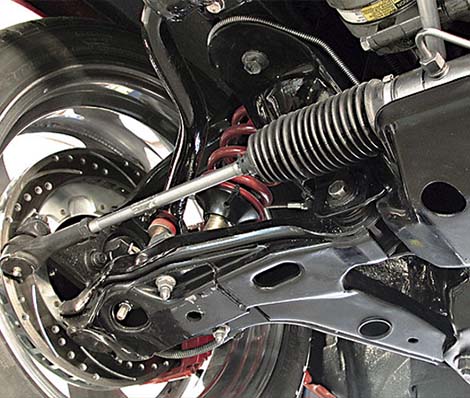

Inspection front and rear suspension components: The shock absorbers or struts, lower and upper suspension components, ball joints, suspension arms, links and stabilizer bar bushings.

Inspection steering components: The fluid condition , power steering pump and lines, rack and steering rods.

Inspection tires and wheels: Check and correct inflation pressure if necessary. Inspect tires and wheels for damage or premature wear.

Lubrication: Chassis elements, lower and upper suspension components, ball joints, suspension arms, stabilizer bar links and steering links (if applicable).

Power steering maintenance: A complete drain and flush of the power steering system which allows us to clean the rack, the steering pump, the valve, the cooler, the hoses and the pipes of the power steering circuit as well as many others components, it removes all deposits of varnish and other contaminants in the system.

Replacement front and rear suspension components: The shock absorbers or struts, lower and upper suspension components, ball joints, suspension arms, links and stabilizer bar bushings.

Replacement the rack, steering rods, pump and power steering lines.

Proper wheel alignment ensures better maneuverability and better control of the vehicle, that the handling of your vehicle is appropriate and also increases the performance and durability of your tires and reduces your fuel consumption.

A road test of the vehicle before delivery, using several simulations and driving maneuvers to test suspension and steering performance to ensure proper operation, maneuverability and road holding.

When driving off-road your vehicle's suspension and steering are put under additional stress due to harsh driving conditions. Here are some tips for optimizing suspension and steering during your off-road adventures:

Suspension Adjustment:

- Make sure your vehicle is equipped with suspension suitable for off-road driving. A more robust suspension with greater ground clearance can better absorb shock and vibration on rough terrain.

Checking Tire Pressure:

- Adjust tire pressure according to the manufacturer's recommendations for off-road driving. Lower tire pressure can improve grip and traction on loose terrain, but be sure to return to normal pressure for on-road driving.

Suspension Component Inspection:

- Regularly check the condition of shock absorbers, springs, stabilizer bars and other suspension components for signs of wear or damage. Replace defective parts as soon as possible.

Suspension Components Protection:

- Install protections for vulnerable suspension components, such as skid plates for shock absorbers and springs, to prevent damage from rocks, tree roots, etc.

Careful Driving:

- Adopt a smoother, more careful ride when driving off-road to reduce stress on the suspension. Avoid overly large obstacles and take your time crossing difficult terrain.

Power Steering Maintenance:

- Make sure the power steering fluid is at the correct level and in good condition. Check the power steering system regularly for leaks and have any leaks repaired as soon as possible.

Checking Ball Joints and Joints:

- Inspect the steering ball joints, suspension ball joints, and other steering joints for signs of wear or play. Replace worn or damaged parts to avoid unstable steering.

Wheel Alignment:

- Make sure your vehicle's wheels are properly aligned to prevent uneven tire wear and improve steering stability when driving off-road.

Driving Attentively:

- Be alert for abnormal steering sensations, such as excessive play in the steering wheel or difficulty maintaining direction, which could indicate a problem with the steering system. Have any problems inspected and repaired as soon as possible.

Undercarrager washing, the importance of undercarrager washing of your vehicle with a high-pressure jet to remove salt, sludge, leaves and stones.

By following these tips, you can optimize your vehicle's suspension and steering for safer, more enjoyable off-road driving. If you experience persistent problems with your suspension or steering, consult a qualified professional for proper diagnosis and repairs.

When looking for service advice on maintaining your vehicle's suspension and steering, here are some important recommendations to follow:

Regular Maintenance:

- Schedule regular suspension and steering checks during your scheduled maintenance appointments. This can help detect potential problems before they become more serious.

Visual Inspection:

- Have the suspension and steering visually inspected for signs of damage, leaks or excessive wear. This may include inspecting shock absorbers, springs, stabilizer bars, ball joints and joints.

Power Steering Control:

- Vérifiez régulièrement le niveau et l'état du liquide de direction assistée. Assurez-vous qu'il est propre et qu'il n'y a pas de fuites au niveau du système de direction assistée.

Wheel Alignment:

- Make sure your vehicle's wheels are properly aligned to prevent uneven tire wear and improve steering stability.

Checking tire wear:

- Monitor tire wear for signs of abnormal wear, which may indicate a problem with the suspension or steering. Have alignment or suspension issues inspected and corrected if necessary.

Listen for abnormal noises:

- Be alert for abnormal noises while driving, such as clicking, squealing, or rattling, which may indicate a problem with the suspension or steering. Have any problems inspected and repaired as soon as possible.

Follow the manufacturer's recommendations:

- Follow the manufacturer's maintenance recommendations for your vehicle's suspension and steering. This may include replacement intervals for wear components, such as shock absorbers, ball joints and joints.

Call a professional: - If you are experiencing problems with your vehicle's suspension or steering, or if you are unsure about the condition of these systems, consult a qualified professional. They can perform thorough inspections and recommend necessary repairs.

By following these service tips you can ensure the proper and safe operation of your vehicle's suspension and steering. Regular, preventative maintenance can help avoid costly problems and unplanned breakdowns.

Complete Automobile & Truck Services.

When you need to repair your vehicle's suspension and steering, it's important to understand potential problems and the steps needed to complete the repairs correctly. Here are some general tips for suspension and steering repairs:

Accurate Diagnosis:

- Before beginning repairs, perform an accurate diagnosis to identify specific problems with the suspension or steering. This may include abnormal noises, unstable steering feel, vibrations, or any other unusual symptoms.

Worn Parts Replacement:

- Replace worn or damaged suspension or steering components, such as shock absorbers, springs, stabilizer bars, ball joints, joints and control arms. Make sure you use quality parts recommended by the manufacturer.

Components Lubrication:

- A properly lubricate suspension and steering components to ensure smooth movement and reduce wear. This can include ball joints, joints and control arms.

Wheel Alignment:

- After making suspension or steering repairs, be sure to have your vehicle's wheels aligned to ensure a stable ride and prevent premature tire wear..

Air suspension repair can be complex due to the specific nature of this system. Here are some general steps to follow when repairing air suspension:

Problem Diagnosing:

- Identify precisely the problem with the air suspension. This may include air leaks, a faulty compressor, faulty sensors, damaged air springs, or other system issues.

Visual Inspection:

- Visual inspection of the entire system for signs of air leaks, physical damage, or worn components. Check air springs, lines, fittings and electrical components.

Pressure Test:

- Pneumatic system pressure test. This can help you locate air leaks and determine if the compressor is working properly.

Compressor Check:

- Check air compressor operation. Make sure it illuminates when the vehicle is started and maintains proper air pressure in the system. If the compressor is defective, it will need to be replaced.

Defective Components Replacement:

- Replace defective or damaged parts, such as air springs, lines, sensors, or compressor, based on diagnosis. Make sure you use quality replacement parts that are compatible with your air suspension system.

Air Leaks Repair:

- Repair by replacing damaged components or using appropriate sealants. Ensure all connections are tight.

Function Test:

- After making repairs, test the operation of the air suspension by raising and lowering the vehicle several times. Check that there are no air leaks and that the vehicle maintains a normal ride height.

Follow the manufacturer's recommendations:

- Follow the manufacturer's maintenance and repair recommendations for your vehicle's suspension and steering. This may include replacement intervals for wearing components and specific specifications for adjustments and alignments.

Safety First:

- Ensure and comply with all safety standards when repairing suspension and steering. Use appropriate tools and ensure the vehicle is properly supported when working under the vehicle.

- Once repairs are completed, our technicians will perform a road test and additional check to ensure the problem has been resolved and that no malfunction.